Replace Warman Pump Spares

We supply interchangeable slurry pump spares with Warman. Depending on different applications, we have different materials, such as high chrome, dual-phase steel, rubber, polyurethane, ceramic, etc.

We are a professional slurry pump and parts manufacturer, we know the exacting tolerances and engineering standards required to build and maintain these Warman pumps, and the Warman pump parts we supplied are identical to the parts from Weir Warman.

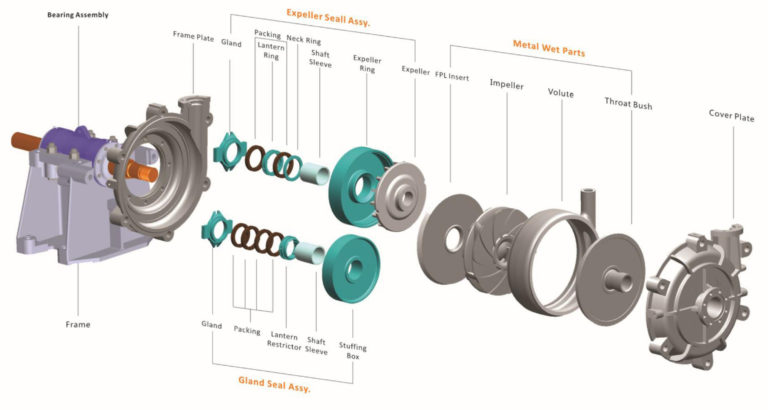

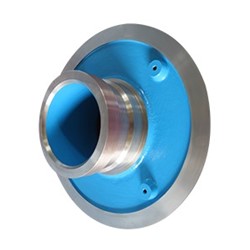

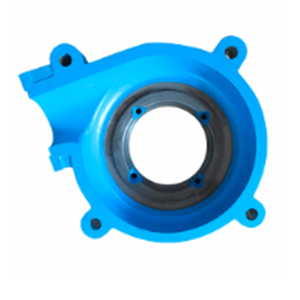

Warman pump parts consist mainly of impellers, volute liner, throat bush, frame plate liner insert, seals, shaft sleeves, bearing assemble, etc.. A good number of our customers use Warman pumps, in dealing with the OEM, customers are constantly faced with high costs, slow delivery times and little to no customer service, so we started to supply Warman pump replacement parts that are fully interchangeable with original Warman pump parts.

Warman pumps are kept on improving over the years, it is difficult to find new replacement parts. But the lead time and the price from Weir Warman are terrible as always, closed cooperation with our customers and resolve our customers’ problem make us develop latest replaced spares, now we can supply a great many replacement parts for Warman pumps, and we are able to make Warman pump parts according to samples even if no drawings.

We are happy to consult with you to recommend the best material such as A05, A07, A49, rubber, ceramic, etc for your application and supply you with qualified spares. All of our pump spares are interchangeable with Warman originals and have the same working life, but we offer a much lower price. We have most of these spares available in our inventory and can deliver within five days after receipt of your purchase order.

The following Warman Pump Parts list provides the basic part number and description for most Warman pump parts, click on one of basic part numbers or descriptions to get more details, or send mail to us directly to find the replacement parts for your Warman pumps.

Warman Pump Parts Number

| 001 | adjusting screw | 003 | Base |

| 004 | bearing housing | 005 | Bearing Assembly |

| 008 | Bearing Sleeve | 009 | Bearing |

| 009D | Bearing(Drive End) | 011 | Clamp Washer |

| 012 | Clamp Bolt | 013 | Cover Plate |

| 015 | Cover Plate Bolt | 016 | Cover Plate Liner |

| 018 | Cover Plate Liner | 023 | Screw/Stud |

| 024 | End Cover | 025 | Shim/(Gasket) |

| 026 | FPL Insert Stud | 027 | End Cover Set Screw |

| 028 | Expeller | 029 | Expeller Ring |

| 029R | Rubber Expeller Ring | 032 | Frame Plate |

| 034 | Frame Plate Blot | 036 | Frame Plate Liner |

| 039 | Frame Plate Stud | 041 | FPL Insert (back liner+expeller+volute liner) |

| 044 | Gland Assembly | 045 | Gland Bolt |

| 046 | Grease Retainer | 060 | Intake Joint |

| 061 | Labyrinth Locknut | 062 | Labyrinth |

| 063 | Lantern Ring | 064 | Impeller O-ring |

| 067 | Neck Ring | 070 | Shaft Key |

| 073 | Shaft | 075 | Shaft Sleeve |

| 078 | Stuffing Box | 079 | Stud |

| 083 | Throat Bush | 085 | Cotter |

| 089 | Bearing Seal | 090 | Shaft Seal |

| 108 | Piston Ring | 109 | Shaft O-ring |

| 110 | Volute Liner | 111 | Packing |

| 117 | Shaft Spacer | 118 | Lantern Restrictor |

| 122 | Stuffing Box Seal | 124 | Volute Cover Seal |

| 125 | FPL Insert Seal | 126 | Gland Bolt |

| 132 | Discharge Joint | 138 | Oil Cup Seat |

| 179 | Bearing Retainer | 217 | Impeller O Ring |

| 239 | Impeller Disassembly Device | 241 | Cup Gland |

| 147 | impeller |

Abrasion Resistant Performance

| Rype | Material Code | Material Description | (MPa) | ak(J/cm2) | HRC | Special Performance | Application |

| Abrasion resistant white iron | A05 | KmTBCr26 | ≥700 | 6-10 | ≥56 | Anti-erosion performance <A07 with certain corrosion resistance | For higher wear condition 5-12 of PH |

| Abrasion resistant white iron | A07 | KmTBCr15Mo | ≥550 | 4-8 | ≥59 | Best anti-erosion performance, corrosion resistance <A04, A05 | For higher wear condition |

| Abrasion resistant white iron | A01 | KmTBCr8 | ≥550 | 6-8 | ≥55 | Anti-erision performance≈90% of A05 | For mud pump |

| Abrasion resistant white iron | A11 | KmTBCrMnMo | ≥400 | 3-6 | 38-42 | Low-grade anti-erosion performance, low hardness, drilling tapping | For microscale fine partical & low-grade abrasion working conditions |

| Anti-wear & anti-corrosive iron | A49 | ≥600 | 43-49 | Abtu-erosion performance, corrosion stability, in low ph environment, abrasion resistance≈A03 | For low-grade PH corrosive environment, expecially suitable fro FGD(PH≥4), Usually used for low acid enviroment | ||

| Anti-wear & anti-corrosive iron | A33 | 35 | Anti-erosion performance≈A03 corrosion resistance | To transport oxidability slurry of PH valve≥1, such as phosphogypsum, HN03, H2SO4, H3PO4, etc. | |||

| A22 | 1200 | 45 | Excellent erosion resistance, higher hardness | For dredging pump casing | |||

| Anti-wear cast steel | A23 | 700 | HB 500-600 | Higher hardness and anti-erode | To transport higher anti-wear & anti-corrosive working condition, such as parts of dredging pump, clean water pump, sewage pump, certain parts of slurry pump | ||

| Anti-wear cast steel | A25 | HB 300-350 | Low hardness, higher abrasion resistance, good weldable performance | For light ecrode and wear condition such as transporting aqueous medium of small gravel |

Natural rubber Performance

| Type | Item Description | R26 | R55 |

| Natural rubber | Hardness | 41±4 | 52±3 |

| Natural rubber | 300% stretching strength N/Cm2 | ≥190 | ≥400 |

| Natural rubber | Breaking strengh N/Cm2 | ≥2000 | ≥2200 |

| Natural rubber | Elongate break % | ≥500 | ≥500 |

| Natural rubber | Pull apart permanet deformation % | ≥30 | ≥25 |

| Natural rubber | Pull strength:μg/Cm2 | ≥40 | ≥40 |

Our Company

Over the past 15 years, Minerco has offered our clients pumping solutions to trusted the world over. Our core team of professional engineers has perfected the centrifugal slurry pump design to give you the best product on the market. Our slurry pumps and spares are interchangeable with the Warman model and parts and come with a 100% risk-free guarantee.

Our Promise- High Quality & Professional Service

Your satisfaction is our number one priority. We welcome your feedback and are always looking for opportunities to improve our service. Our business philosophy is simple:

Quality control– We want to assure you of the perfection of our products, which is why we employ in-house quality management and process inspection team.

Fast, reliable service– We aim to meet the demands of all of our customers quickly and effectively. Our work is not complete until you are satisfied.

Supply support capacity– We understand no two operations are the same and that different jobs require different tools- that is why we take pride in the fact that it is well-stocked with a wide, diverse range of products.

Competitive pricing– We believe we offer the best product possible for the cost.