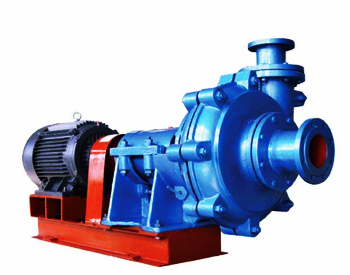

ZJ Series Centrifugal Slurry Pump

Product Description

As one of the earliest centrifugal slurry pump manufacturers, our ZJ series slurry pump has a single-stage and centrifugal-type suction design. The wet part is composed of high chrome white iron and possesses anti-abrasive, anti-shock properties, which optimize performance, extend the life of the wetted parts of pumps, and increase cost-effectiveness. The discharge diameter of the horizontal model ranges between 650mm-40mm. The heads may be customized by selecting different impellers to suit your purpose, or the impeller installed may be cut to your specifications.

Our pump designs are not only constructed to withstand shocks, but also high pressures. These models are ideal for multi-stage operations, such as long tailings disposal pipelines. Here, the pumps are constructed with a split casing and light replaceable liners, and the strength is provided by the two halves of the casing being bolted together. The liners are held in position by the housing, which accommodates all internal and external loads.

Product Features

Main Application

- Double liners metal structure

- Vertical middle split casing

- Re-positional discharge port- 8 different positions at 45-degree angles

- Variable bearing lubrication options, depending on the design of bearing housing.

- Thin-oil lubrication may be used for box type

- Grease lubrication may be used for cylinder type

- Thin-oil or grease lubrication may be used for bearing housings with an inserted cover.

This type of centrifugal slurry pump can be used in series or working together in parallel and is widely used in power plants and the metallurgy, coal washing, building, and chemical industries. Examples of uses include transport of abrasive slurries like that found in the concentrate and tail slurry of ore dressing plants, slag handling in power plants, transport of coal mud, medium to heavy coal separation, and sand transport in shore-based work. The maximum weight concentration of slurry that can be processed varies with the type, approximately 45% for mortar slurry and 65% for mining slurry. This model may use a DC, V-belt, hydraulic coupling, of frequency speed adjusting transmission type.

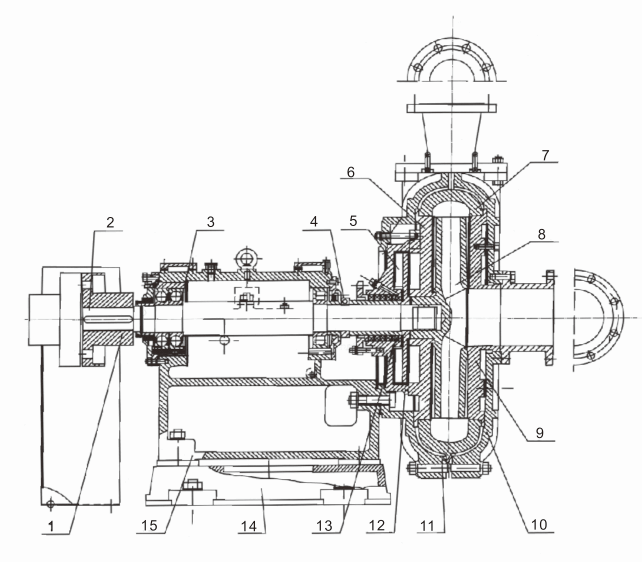

Centrifugal Slurry Pump Structural Drawing

| 1. Coupling | 2. Shaft |

| 3. Bearing Housing | 4. Disassembly Ring |

| 5. Expeller | 6. Frame Plate Liner Insert |

| 7. Volute Liner | 8. Impeller |

| 9. T Roatbushing | 10. Cover Plate |

| 11. Frame Plate | 12. Stuffing Box |

| 13. Lantem Ring | 14. Base |

| 15. Support |

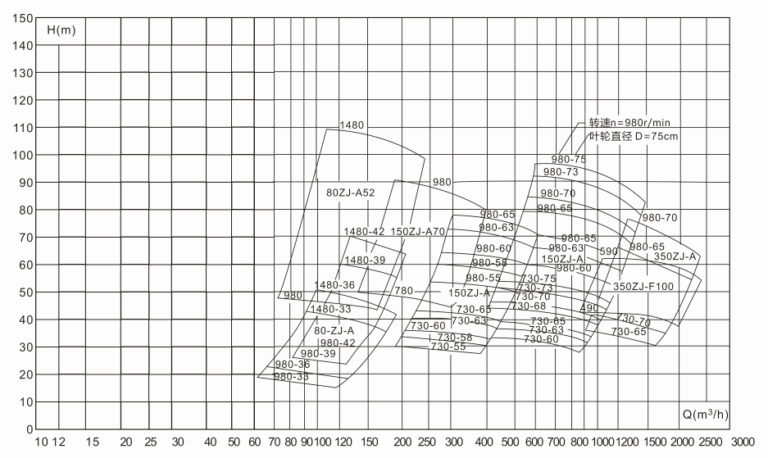

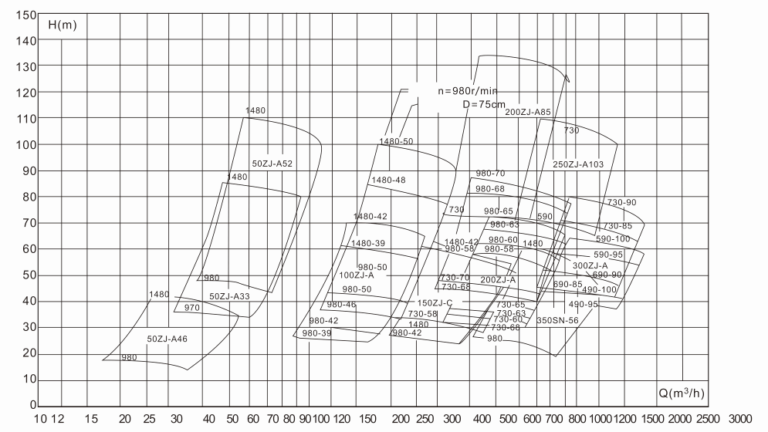

Selection & Performance Chart

ZJ Slurry Pump Performance Chart

| Pump Model | Max.Power (kw) | Capacity m³/h | Head H(m) | Speed n(r/min) | Max.EFF.(%) | NPSH (m) | Particle Max. Size (mm) | Pump Weight (kg) |

| 300ZJ-A100 | 450 | 464-1826 | 15.3-65.2 | 300-590 | 81.1 | 3 | 88 | 5265 |

| 300ZJ-A95 | 400 | 441-1735 | 13.8-58.8 | 300-590 | 78.1 | 3 | 88 | 5770 |

| 300ZJ-A90 | 560 | 505-1844 | 21.2-79.9 | 400-730 | 87.8 | 3.9 | 85 | 5005 |

| 300ZJ-A85 | 450 | 477-1742 | 18.9-71.3 | 400-730 | 79.8 | 3.8 | 85 | 4965 |

| 300ZJ-A70 | 630 | 635-2333 | 16.0-76.8 | 490-980 | 80.4 | 3.9 | 92 | 3560 |

| 300ZJ-A65 | 500 | 589-2166 | 13.8-66.2 | 490-980 | 77.4 | 3.7 | 92 | 3531 |

| 300ZJ-A56 | 250 | 395-1568 | 9.7-46.0 | 400-980 | 80.9 | 3.5 | 96 | 3030 |

| 250ZJ-A103 | 560 | 402-1573 | 29.7-110.5 | 400-730 | 74.5 | 2.8 | 69 | 5085 |

| 250ZJ-A96 | 560 | 403-1466 | 25.4-93.7 | 400-730 | 77.8 | 3.5 | 69 | 5035 |

| 250ZJ-A90 | 450 | 378-1374 | 22.3-82.4 | 400-730 | 73.8 | 3.4 | 69 | 4980 |

| 250ZJ-A85 | 800 | 376-1504 | 30.1-128.7 | 490-980 | 76.5 | 3.5 | 76 | 4530 |

| 250ZJ-A83 | 800 | 367-1469 | 28.7-122.7 | 490-980 | 75.5 | 3.5 | 76 | 4514 |

| 250ZJ-A80 | 710 | 354-1416 | 26.7-114.0 | 490-980 | 73.5 | 3.4 | 76 | 4490 |

| 250ZJ-A78 | 630 | 415-1796 | 21.1-102.5 | 490-980 | 71.5 | 3.2 | 76 | 4474 |

| 250ZJ-A75 | 560 | 300-1480 | 20.8-97.5 | 490-980 | 77.5 | 3 | 77 | 3480 |

| 250ZJ-A73 | 500 | 292-1441 | 19.7-92.4 | 490-980 | 76.5 | 3 | 77 | 3456 |

| 250ZJ-A70 | 450 | 280-1381 | 18.1-84.9 | 490-980 | 74.5 | 2.9 | 72 | 3446 |

| 250ZJ-A68 | 450 | 272-1342 | 17.1-80.1 | 490-980 | 73.5 | 2.7 | 77 | 3437 |

| 250ZJ-A65 | 315 | 299-1249 | 15.4-71.0 | 490-980 | 76.5 | 3 | 72 | 3020 |

| 250ZJ-A63 | 315 | 290-1211 | 14.4-66.7 | 490-980 | 75.9 | 3 | 77 | 3008 |

| 250ZJ-A60 | 280 | 276-1153 | 13.1-60.5 | 490-980 | 73.9 | 2.8 | 72 | 2991 |

| 200ZJ-A85 | 560 | 221-907 | 32.0-133.7 | 490-980 | 70.5 | 2.8 | 54 | 4110 |

| 200ZJ-A75 | 355 | 225-900 | 22.8-102.9 | 490-980 | 74.1 | 3 | 56 | 3070 |

| 200ZJ-A73 | 355 | 219-876 | 21.6-97.5 | 490-980 | 73.1 | 3 | 56 | 3056 |

| 200ZJ-A70 | 315 | 205-976 | 19.4-86.4 | 490-980 | 75.6 | 2.8 | 56 | 2465 |

| 200ZJ-A68 | 315 | 199-948 | 18.3-81.5 | 490-980 | 74.6 | 2.8 | 56 | 2453 |

| 200ZJ-A65 | 250 | 235-950 | 16.4-72 | 490-980 | 79.6 | 2.5 | 62 | 2323 |

| 200ZJ-A63 | 250 | 228-921 | 15.4-37.6 | 490-980 | 78.6 | 2.5 | 62 | 2311 |

| 200ZJ-A60 | 185 | 218-870 | 13.9-62 | 490-980 | 83.5 | 2.5 | 67 | 2223 |

| 200ZJ-A58 | 185 | 211-841 | 13-57.9 | 490-980 | 82.5 | 2.5 | 62 | 2214 |

| 150ZJ-A70 | 185 | 93-401 | 20-91.2 | 490-980 | 62.1 | 2 | 37 | 2245 |

| 150ZJ-A65 | 200 | 150-600 | 17.4-75.7 | 490-980 | 70.8 | 2.5 | 48 | 2223 |

| 150ZJ-A63 | 185 | 146-582 | 16.3-71.1 | 490-980 | 69.8 | 2.5 | 48 | 2211 |

| 150ZJ-A60 | 160 | 135-550 | 14.7-63.5 | 490-980 | 75.9 | 2.5 | 48 | 2203 |

| 150ZJ-A58 | 132 | 131-532 | 13.7-59.3 | 490-980 | 74.9 | 2.5 | 48 | 2033 |

| 150ZJ-A58 | 110 | 124-504 | 12.3-53.4 | 490-980 | 72.9 | 2.3 | 48 | 2019 |

| 150ZJ-C58 | 160 | 134-596 | 12.8-61 | 490-980 | 69.1 | 7 | 75 | 2063 |

| 150ZJ-A57 | 110 | 95-427 | 13.2-56.3 | 490-980 | 67.8 | 1.8 | 32 | 2023 |

| 150ZJ-A50 | 75 | 115-460 | 9.5-43.1 | 490-980 | 76.8 | 2.5 | 48 | 1735 |

| 150ZJ-A48 | 75 | 111-442 | 8.7-39.7 | 490-980 | 75.8 | 2.5 | 48 | 1728 |

| 150ZJ-C42 | 132 | 142-550 | 12.1-62.8 | 700-1480 | 77.1 | 2.2 | 69 | 1605 |

| 100ZJ-A50 | 160 | 85-360 | 20.5-100.2 | 700-1480 | 69.6 | 2.5 | 34 | 1475 |

| 100ZJ-A46 | 132 | 79-331 | 17.3-84.4 | 700-1480 | 67.6 | 2.3 | 34 | 1461 |

| 100ZJ-A42 | 90 | 66-275 | 14.7-70.8 | 700-1480 | 71 | 2.5 | 35 | 1075 |

| 100ZJ-A39 | 75 | 61-255 | 12.6-61 | 700-1480 | 69 | 2.4 | 35 | 1064 |

| 100ZJ-B42 | 90 | 83-365 | 12.7-66.8 | 700-1480 | 71.6 | 2.5 | 40 | 1085 |

| 100ZJ-A36 | 55 | 61-245 | 9.7-49.5 | 700-1480 | 71.6 | 2 | 32 | 1010 |

| 100ZJ-A33 | 45 | 56-225 | 8.2-41.6 | 700-1480 | 69.6 | 1.8 | 32 | 1003 |

| 80ZJ-A52 | 160 | 51-242 | 22.1-109.8 | 700-1480 | 56.3 | 2.1 | 21 | 1465 |

| 80ZJ-A42 | 75 | 61-204 | 14.4-70.4 | 700-1480 | 66.7 | 2.5 | 24 | 1053 |

| 80ZJ-A39 | 55 | 57-189 | 12.4-60.7 | 700-1480 | 64.7 | 2.4 | 24 | 1042 |

| 80ZJ-A36 | 45 | 46-190 | 9.6-51.4 | 700-1480 | 67.7 | 2.5 | 24 | 980 |

| 80ZJ-A33 | 37 | 43-174 | 8-43.2 | 700-1480 | 65.7 | 2.3 | 24 | 973 |

| 65ZJ-A30 | 15 | 23-79 | 7.4-34.8 | 700-1480 | 63.5 | 2 | 19 | 504 |

| 65ZJ-A27 | 11 | 20-71 | 6-28.2 | 700-1480 | 61.5 | 1.8 | 19 | 500 |

| 50ZJ-A50 | 90 | 27-111 | 22.3-110.7 | 700-1480 | 45.1 | 3 | 13 | 1378 |

| 50ZJ-A46 | 55 | 23-94 | 17.9-85.8 | 700-1480 | 44.7 | 1.4 | 14 | 1082 |

| 50ZJ-A33 | 18.5 | 12-54 | 7.7-42.5 | 700-1480 | 42.1 | 2.9 | 13 | 537 |

| 40ZJ-A17 | 7.5 | 4-23 | 9-44.6 | 700-1480 | 52.4 | 2.5 | 11 | 121 |

Centrifugal Slurry Pump Live Application

Pump Selection Guide From Slurry Pump Manufacturers

Export Slurry Pump, Chemical Pump, Vertical Slurry Pump,Sand Pump

Slurry Pump Manufacturers

Over the past 15 years working as one of the slurry pump manufacturers, Minerco has offered our clients pumping solutions to trusted the world over. Our core team of professional engineers has perfected the centrifugal slurry pump design to give you the best product on the market. Our slurry pumps and spares are interchangeable with the Warman model and parts and come with a 100% risk-free guarantee.

Our Promise- High Quality &Professional Service

Your satisfaction is our number one priority. We welcome your feedback and are always looking for opportunities to improve our service. We would like to be your own slurry pump manufacturers.

Quality control– We want to assure you of the perfection of our products, which is why we employ in-house quality management and process inspection team.

Fast, reliable service– We aim to meet the demands of all of our customers quickly and effectively. Our work is not complete until you are satisfied.

Supply support capacity– We understand no two operations are the same and that different jobs require different tools- that is why we take pride in the fact that it is well-stocked with a wide, diverse range of products.

Competitive pricing– We believe we offer the best product possible for the cost. And you could get all the products from slurry pump manufcturers directly.