Slurry Pump

The slurry pump has a non-clog design for pumping liquid containing solid particles. They vary in design and construction to accommodate multiple types of slurry with a wide range of concentrations of solids, sizes of solid particles, shapes of solid particles, and compositions of solution. Slurry pumps are more robust than water pumps, as they are constructed with abrasion-resistant materials and replaceable wet parts. Both centrifugal and positive displacement models can be used to pump slurry. Centrifugal slurry pumps can have between bearing-supported shafts with split casings or rubber- or metal-lined casings. Configurations include horizontal, vertical suspended, and submersible.

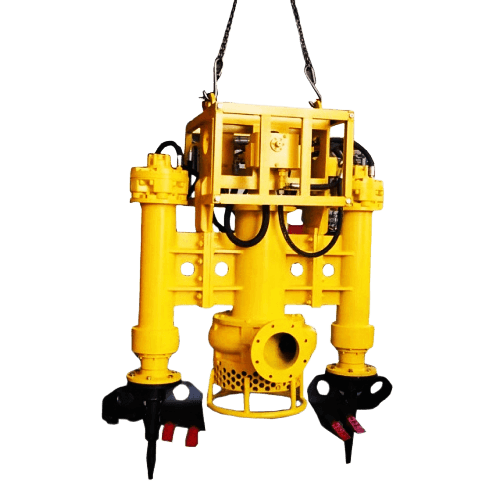

Submersible Slurry Pump

Our submersible slurry pump is a device that has a hermetically sealed motor coupled closely to the pump body. The entire unit is submerged in the liquid to be pumped. The main advantage of this type of pump is that it prevents cavitation, a problem associated with a high elevation difference between the pump and surface of the liquid to be pumped. The difference between it and the submersible sewage pump is that our slurry pump is designed to pump slurry or fluid with sand.

Chemical Pump

Our chemical pump is designed according to API610 and VDMA24297 (light and medium-heavy) standards. It can pump corrosive chemical liquids with or without particles and in high and low temperatures.

This model is mainly used in refineries, coal processing, low-temperature projects, petrochemical industry, seawater desalinization plants, heating systems, nuclear power stations, and chemical and processing industries, especially paper and pulp, sugar, and water.

Vertical Slurry Pump

This heavy-duty cantilever sump pump is designed for applications requiring greater durability than conventional vertical process pumps can offer. It is constructed with hard alloy wear parts or full elastomer protection for all submerged components, allowing this pump to be used for applications where the medium is highly corrosive.

Common applications include transport of slurry with abrasive, coarse particles and high concentration. They are widely used in metallurgy, mining, coal, electric power, building materials, and environmental protection.

Sand Pump

Sand gravel pumps are designed to accommodate very large particles for gravel and dredging operations. They are designed for the continuous transport of the most abrasive slurry, containing solids too large for a standard slurry pump. They are suitable for delivering slurry in mining, explosive sludge in metal melting, and dredging in rivers and other bodies of water. They are also suitable for accommodating abrasive and corrosive slurry with solids with maximum concentrations of wt.45% (ash) and wt.60%.

Split Case Pump

The split case pump is a single-stage, non-self-priming, between bearing, centrifugal volute pump. The axially split design allows easy removal of the top casing and access to the pump components (bearings, wear rings, impeller, and shaft seal) without disturbing the motor or pipework.

The independent bearing housing allows for ease of maintenance without removal of the top casing. The double volute design reduces the radial load on the shaft, extending component life, minimizing vibration, and reducing noise pollution. This model is highly efficient, low-maintenance, and has a long pump life, all of which contribute to an overall lower cost of operation.

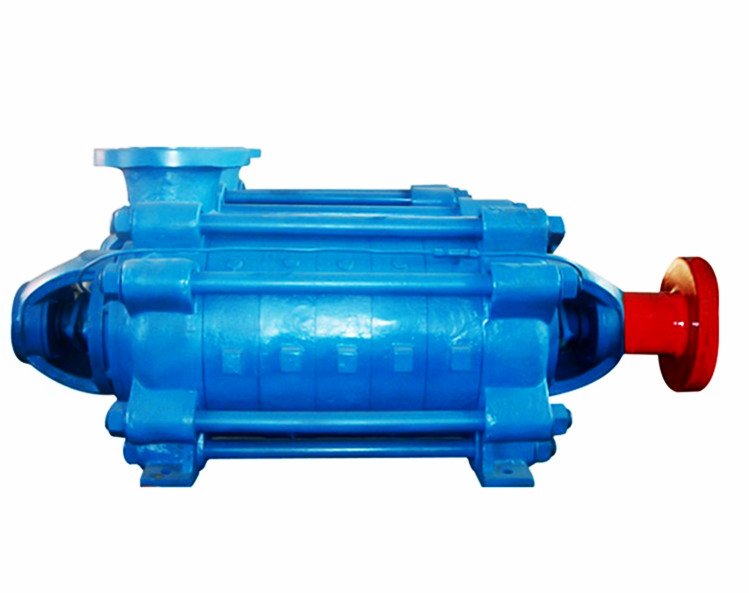

Multistage Pump

The multi-stage pump is a centrifugal pump combined with inlet, outlet, and middle sections. Its output water pressure can be very large, depending on the centrifugal force generated by the rotation of the impeller. When the gas density reaches the working range of the mechanical vacuum pump and is drawn out, a high vacuum is gradually obtained. Multi-stage pumps rely on volume changes in the pump cavity to achieve suction, compression, and exhaust, so it is considered a centrifugal pump with variable volume.

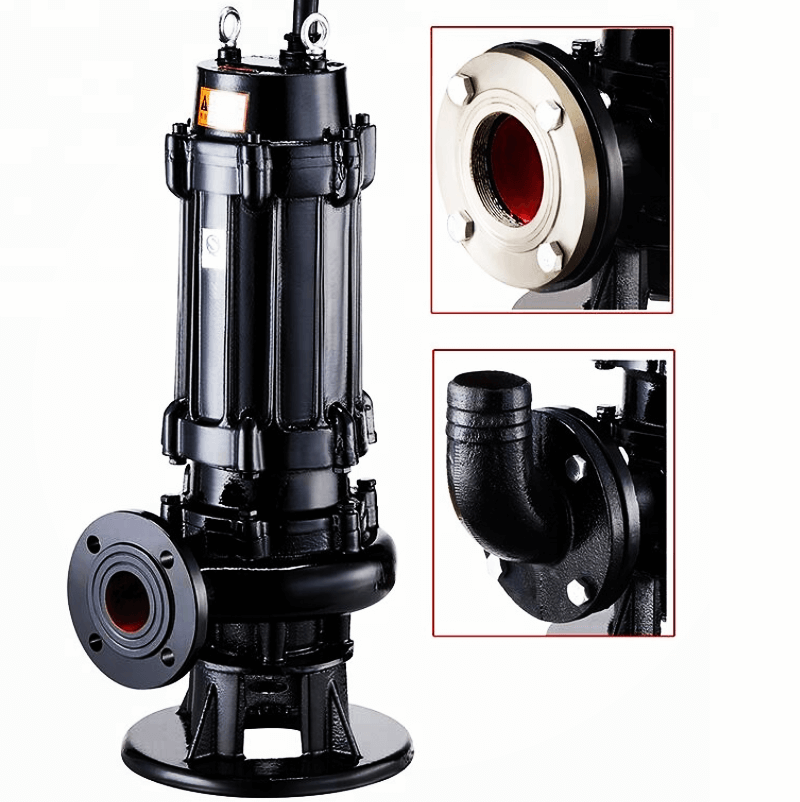

Water Pump

Water pumps transport or pressurizes liquids. They transmit the mechanical energy of the prime mover or other external energy to the liquid, which increases its energy. They are mainly used to transport liquids, including water, oil, acidic and alkaline liquids, emulsions, suspension emulsions, and liquid metals. They can also transport gas mixtures and liquids containing suspended solids. The technical parameters of pump performance include flow, suction, head, shaft power, waterpower, and efficiency. According to different working principles, pump types can be further classified as volume pumps, vane pumps, or other types. Positive displacement pumps use the change in the volume of their working chambers to transfer energy. Vane pumps use the interaction of rotating blades and water to transfer energy. Other types include centrifugal pumps, axial flow pumps, and mixed flow pumps.

Valve Series

Valves are piping accessories used to open and close a pipeline, control flow direction, and adjust and control the parameters (temperature, pressure, and flow) of the medium conveyed. They are control components in the fluid delivery system and have functions including cut-off, regulation, diversion, prevention of backflow, voltage stabilization, shunting, or pressure relief. Valves for fluid control systems range from the simplest of shut-off valves to those used in extremely complex automatic control systems. They can be used to control the flow of various types of fluid, including air, water, steam, various corrosive media, muds, oils, liquid metals, and radioactive media. According to function, they can be categorized as shut-off valves, check valves, regulating valves, etc. Valves are constructed from a variety of materials, including cast iron, cast steel, stainless steel (201, 304, 316, etc.), chrome-molybdenum steel, chrome-molybdenum vanadium steel, dual-phase steel, plastic, and non-standard custom materials.

OEM

OEM metal castings are iron, steel, or aluminum castings produced by foundries according to customer drawings and requirements. Also we produce and OEM ceramic impeller, rubber impeller etc pump parts.