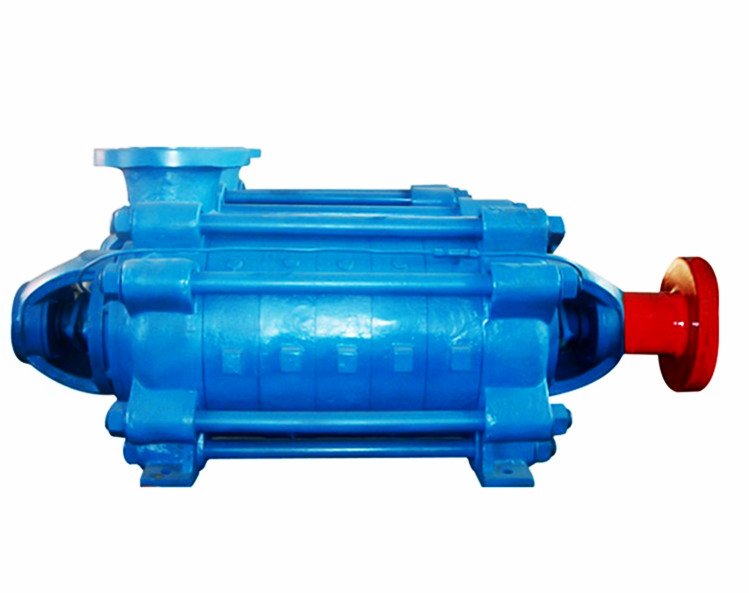

Multistage Centrifugal Pump

The basic structure of a multistage centrifugal pump involves a water inlet section, water outlet section, middle section, tail cover, impeller, pump body, pump shaft, bearing, seal ring, and stuffing box. Here, we will discuss each feature in detail.

1.The water inlet section, water outlet section, and middle section are also called pump casings and are the main body of a multi-stage pump. They play a supporting and fixing role, and are connected with the bracket on which the bearing is installed.

2. The impeller is the core part of a multistage centrifugal pump. It has both high speed and high output. The blades on the impeller play a major role in the movement of fluid through the pump. The inner and outer surfaces of the impeller need to be smooth to reduce the frictional loss of water flow and must pass the static balance test before assembly.

3. The role of the pump shaft is to connect the multistage pump and the motor through coupling to transmit the torque of the motor to the impeller. It is the main component for transmitting mechanical energy.

4. The bearing is a component that is sleeved on the pump shaft to support it. There are two types of bearings- rolling bearings and sliding bearings. Rolling bearings use “butter” as a lubricant, and attention should be paid to how much is used. Generally, the butter volume is 2/3 to 3/4. Too much butter will generate heat; too little will generate noise and heat.

While the multistage centrifugal pump is in operation, the temperature of the bearings is around 60 degrees and should not rise above 85 degrees. If the temperature is high, find the reason (whether there are impurities in the lubrication, whether the oil is black, or whether it has water, for example) and address the issue. If you cannot, please contact our team of experts for advice.

5. The sealing ring is also called the leakage reducing ring. Excessive clearance between the impeller inlet and the multistage pump casing causes the water in the high-pressure area of the pump to flow to the low-pressure area through this clearance, which can affect the multistage pump output and reduce efficiency. If clearance is too small, it will cause friction between the impeller and the pump casing, causing wear. A seal ring is installed at the inner edge of the multistage pump casing and the external assistance of the impeller in order to increase backflow resistance and reduce the internal leakage, extending the service life of the impeller and the pump casing.

6. The stuffing box is composed of packing, a water sealing ring, a packing tube, a packing gland, and a water sealing tube. The function of the stuffing box is to close the gap between the pump casing and the pump shaft and to prevent the water in the pump from flowing outside and outside air from entering. The vacuum must always be kept inside the pump. When the pump shaft and the filler produce friction to generate heat, it is necessary to rely on the water seal tube to hold the water in the water seal ring to cool the filler and keep the pump running normally. Therefore, special attention must be paid to inspection of the stuffing box while performing a running inspection of the multistage centrifugal pump. The packing will need to be replaced after approximately 600 hours of operation.