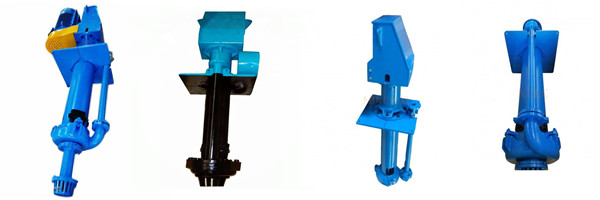

Vertical Mining Pumps Installation and Disassembly

Unsure how to begin to install or disassemble your new vertical mining pumps? Below, we explain how to install and to disassemble the vertical mining pump in a step-by-step manner.

To begin, the vertical mining pump is connected to the motor through the elastic coupling. When viewed from the direction of the motor, the pump rotates clockwise. Install the double-row bearing on the pump shaft, then the bearing spacer, and the upper bearing inner ring in this order.

1. Put the pump shaft containing the bearing into the bearing body, and install the bearing sealing gland and water retaining ring.

2. Install the upper bearing, bearing gland, bearing sleeve, and lock nut in turn.

3. Adjust the bearing clearance- Adjust the shaft to the lower end of the bearing body until it stops. Fix one round nut; the other round nut is not fixed. Use a spudger and dial indicator to adjust the axial clearance. The general clearance is 0.015 ~ 0.025mm. Then, tighten the nut and install the pump coupling.

4. Install and fix the connecting pipe, fixing plate, back cover, impeller, pump body, elbow, and outlet pipe. Note: the gap between the impeller and the front end of the pump casing is 2 ~ 2.5mm.

5. IInstall the motor base and motor with electrical connection; that is, complete the assembly process of the pump.

6. Disassemble the vertical mining pumps according to steps described above in reverse.

If you experience difficulty in this process, please contact us! Our team of experts can help guide you through the process and get your operation underway more quickly.