G/GH Gravel Pump

Product Description

G/GH gravel pumps are type Warman gravel pump which are designed to accommodate the most difficult, most highly abrasive slurries containing solids too large to be conveyed by a regular pump. They are suitable for delivering slurries in mining, explosive sludge in metal melting, dredging in dredger and river courses, and other fields. This model is a high head pump. To increase efficiency, this pump offers a variable frequency drive, silicon-controlled speed control, and multiple speeds and variants.

The gravel pump flow channel is wide, good cavitation performance, high efficiency, wear resistance. It is mainly used for continuous conveying of abrasive materials that are too large for general slurry pumps to convey. It is suitable for dredging, sand suction gravel, dredging rivers, river sand mining, and metal smelting slag transportation.

Shaft seal form: packing seal, impeller seal, mechanical seal.

Transmission mode: V-belt transmission, elastic coupling transmission, gear reducer transmission, hydraulic coupling transmission, variable frequency drive, silicon controlled speed control With multiple speeds and multiple variants, the pump runs under optimal conditions. Long service life, high operating efficiency, can meet a variety of harsh transportation conditions.

Product Features

Main Application

Construction of this sand and gravel pump is of single casing connected by means of clamp hands and wide wet-passage. The wet-part are made of Ni-hard and high chromium abrasion-resistance alloys. The discharge direction of the pump can be oriented in any direction of 360. This type of gravel pump possesses the advantages of easy installation and operation, good performance of NPSH and abrasion-resistance

Series G/GH sand and gravel pumps are widely used in the mining, coal washing, power plant, metallurgy, petrochemical, building material, dredging, and other industrial departments, etc.

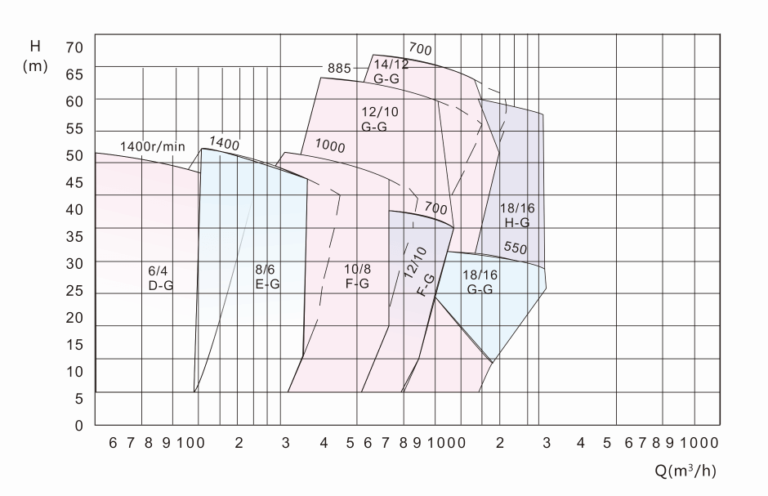

Gravel Pump Performance Chart

Warman Gravel Pump Performance Chart

| Pump Model | Allowable Max.Power(kw) | Capacity m³/h | Capacity L/S | Head H(m) | Speed n(r/min) | Max.EFF.(%) | NPSH(m) | Impeller.Dia(mm) |

| 6/4D-G | 60 | 36-250 | 10-70 | 5-52 | 600-1400 | 58 | 2.5-3.5 | 378 |

| 8/6E/G | 120 | 126-576 | 35-160 | 6-45 | 800-1400 | 60 | 3-4.5 | 378 |

| 10/8S-G | 560 | 216-936 | 60-260 | 8-52 | 500-1000 | 65 | 3-7.5 | 533 |

| 10/8F-G | 260 | 216-936 | 60-260 | 8-52 | 500-1000 | 65 | 3-7.5 | 533 |

| 10/8S-GH | 560 | 180-1440 | 50-400 | 24-80 | 500-950 | 77 | 2.5-5 | 711 |

| 12/10F-G | 260 | 360-1440 | 100-400 | 10-60 | 400-850 | 65 | 1.5-4.5 | 667 |

| 12/10G-G | 600 | 360-1440 | 100-400 | 10-60 | 400-850 | 65 | 1.5-4.5 | 667 |

| 12/10G-GH | 600 | 288-2808 | 80-780 | 16-80 | 350-700 | 73 | 2.0-10.0 | 950 |

| 14/12G-G | 600 | 576-3024 | 160-840 | 8-70 | 300-700 | 68 | 2.0-8.0 | 864 |

| 16/14G-G | 600 | 720-3600 | 200-1000 | 18-44 | 300-500 | 70 | 3.0-9.0 | 1016 |

| 16/14TU-G | 1200 | 324-3600 | 90-1000 | 26-40 | 300-500 | 72 | 3.0-6.0 | 1270 |

| 18/16G-G | 600 | 420-4320 | 200-1200 | 12-48 | 250-500 | 72 | 3.0-6.0 | 1067 |

| 18/16TU-G | 1200 | 720-4320 | 200-1200 | 12-48 | 250-500 | 72 | 3.0-6.0 | 1067 |

Gravel Pump Live Application

Pump Selection Guide

Export Slurry Pump,Chemical Pump,Vertical Slurry Pump,Sand Pump

Our Company

Over the past 15 years, Minerco has offered our clients pumping solutions to trusted the world over. Our core team of professional engineers has perfected the centrifugal slurry pump design to give you the best product on the market. Our slurry pumps and spares are interchangeable with the Warman model and parts and come with a 100% risk-free guarantee.

Our Promise- Reliable Quality & Professional Service

Your satisfaction is our number one priority. We welcome your feedback and are always looking for opportunities to improve our service. Our business philosophy is simple:

Quality control– We want to assure you of the perfection of our products, which is why we employ in-house quality management and process inspection team.

Fast, reliable service– We aim to meet the demands of all of our customers quickly and effectively. Our work is not complete until you are satisfied.

Supply support capacity– We understand no two operations are the same and that different jobs require different tools- that is why we take pride in the fact that it is well-stocked with a wide, diverse range of products.

Competitive pricing– We believe we offer the best product possible for the cost.