AF Series Froth Pump

Product Description

The viscous chemical froth produced for mineral processing and oilsand extraction, though necessary, can quickly overwhelm the capabilities of a standard slurry pump. To address this concern, specifically the AF series froth pump to convey frothy, corrosive slurry. Among their many benefits, when working, these pumps can effectively eliminate the foam of slurry weight and can maintain normal function, despite insufficient incoming materials. They are especially suitable for various flotation processes and are also ideal for conveying foamed paste.

Product Features

Main Application

- Heavy-duty construction with through-bolt design provides ease of maintenance and increased productivity

- Casings are fully lined with ductile iron to assure strength, durability, and extended service life

- Large diameter, slow turning, impellers minimize wear and lower TOC

- Large, open internal passages reduce internal velocities, increasing efficiency and reducing operating costs

- Unique impeller design for most difficult froth applications

- Thick elastomer or metal bolt-in liners provide superior corrosion resistance

- Liners can be easily changed and intermixed to prolong the life of the pump and reduce associated maintenance costs

- Minimal shaft/impeller overhang reduces shaft deflection and increases packing life

- The cartridge-style bearing assembly allows for easy maintenance in a clean environment without removal of the pump, minimizing production delays and extending life of bearings

- Standard AH can be converted by replacing cover plate, throat bush, and impeller

- Full flush, low flow, or dry running centrifugal seals conserve water and cut operating costs

As the froth pump gain popularity and promotion, they have become widely used in metallurgical, mining, coal one, and chemical engineering industries, and are relied upon to handle abrasive and corrosive slurries with foam and froth.

Froth Pump Live Application

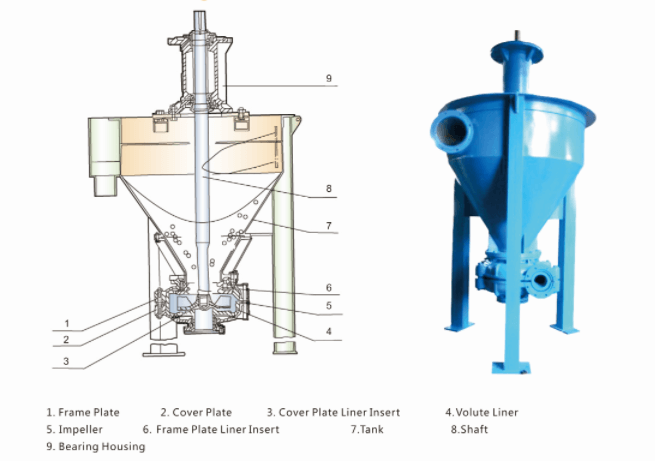

Froth Pump Construction Drawing

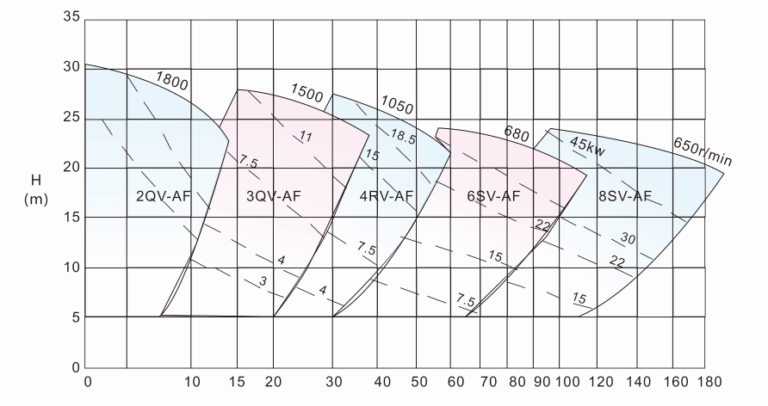

AF Froth Pump Selection Chart

AF Forth Pump Performance Chart

| Pump Model | Capacity Q m³/h | Head H(m) | Speed n(r/min) | EFF.(%) | Installed with Power(kw) | Diamcter Inlet(mm) | Diamcter Outlet(mm) |

| 2QV-AF | 7.6-42.8 | 6-29.5 | 800-1800 | 45 | 15 | 100 | 50 |

| 3QV-AF | 23-77.4 | 5-28 | 700-1500 | 55 | 18.5 | 150 | 75 |

| 4RV-AR | 33-188.2 | 5-28 | 500-1050 | 55 | 37 | 150 | 100 |

| 6SV-AF | 80-393 | 5-25 | 250-680 | 55 | 75 | 200 | 150 |

| 8SV-AF | 126-575 | 5.8-25.5 | 350-650 | 55 | 110 | 250 | 200 |

Pump Selection Guide

Export Slurry Pump,Chemical Pump,Vertical Slurry Pump,Sand Pump, Froth Pump

Our Company

Over the past 15 years, Minerco has offered our clients pumping solutions to trusted the world over. Our core team of professional engineers has perfected the centrifugal slurry pump design to give you the best product on the market. Our slurry pumps and spares are interchangeable with the Warman model and parts and come with a 100% risk-free guarantee.

Our Promise- High Quality & Professional Service

Your satisfaction is our number one priority. We welcome your feedback and are always looking for opportunities to improve our service. Our business philosophy is simple:

Quality control– We want to assure you of the perfection of our products, which is why we employ in-house quality management and process inspection team.

Fast, reliable service– We aim to meet the demands of all of our customers quickly and effectively. Our work is not complete until you are satisfied.

Supply support capacity– We understand no two operations are the same and that different jobs require different tools- that is why we take pride in the fact that it is well-stocked with a wide, diverse range of products.

Competitive pricing– We believe we offer the best product possible for the cost.