Ceramic Valve

Ceramic valve can greatly improve the fluency and sealing of industrial piping systems. Improving the safety and stability of supporting equipment operating systems will play an active role in promoting environmental protection and energy conservation, and environmental protection. The structural ceramic material has less deformation, and the tensile strength, compressive strength, and hardness are very high. With today’s technological innovation, ceramic valves are more and more highly valued and accepted by domestic and international, and they are more and more widely used. They are government-supported science and technology projects.

Product Description

Metal valves cannot withstand severe working conditions such as those found in the chemical, coal, and petroleum industries. The high wear and corrosion of these mediums cause metal valves to leak easily and making them unable to resist corrosion or damage from large torque.

Ceramic valves, however, use high-performance structural materials, which have excellent self-cleaning properties, are resistant to high wear and strong corrosion, have a long service life and can be used widely, especially with industrial chemicals.

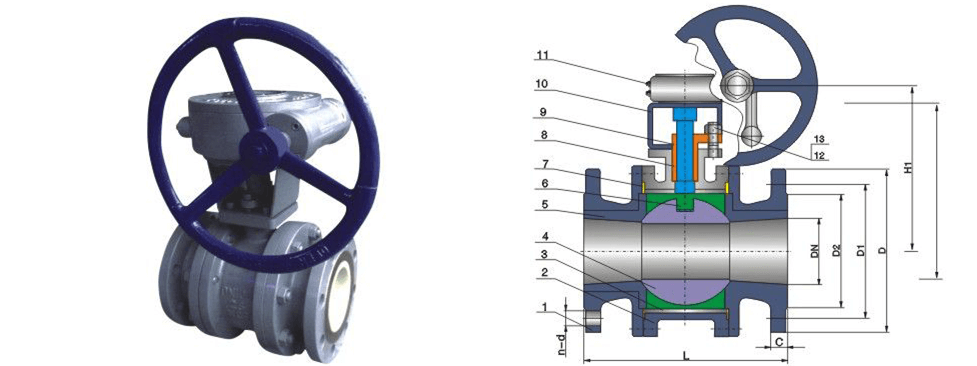

Product Structure

Product Features

Product Parameters

- Ceramic valves, sealing parts, and wearing parts are made of modern, high-tech ceramic structural materials, which improves sealing properties and abrasion and corrosion resistance, extending the life of the valves.

- The use of ceramic valves can greatly reduce the number of valve repairs and replacements in an operation, improving the safety and stability of supporting equipment operating systems, minimizing equipment repair costs.

- The use of ceramic valves can improve the tightness of industrial piping systems, minimize leakage, and protect the environment.

| Structure Length | GB/T 12221 |

| Flange Dimension | GB/T 9113.1 |

| Inspection and Test | GB/T 9092 |

| Carbon Steel | GB/T 12229 |

| Stainless Steel | GB/T 12230 |

| Mark | GB/T 12220 |

Valve Selection Guide

Export Ball Valve, Knife Gate Valve, Ceramic Valve, Gate Valve

Our Company

Over the past 15 years, Minerco has offered our clients pumping solutions to trusted the world over. Our core team of professional engineers has perfected the centrifugal slurry pump design to give you the best product on the market. Our slurry pumps and spares are interchangeable with the Warman model and parts and come with a 100% risk-free guarantee.

Our Promise- Reliable Quality & Professional Service

Your satisfaction is our number one priority. We welcome your feedback and are always looking for opportunities to improve our service. Our business philosophy is simple:

Quality control– We want to assure you of the perfection of our products, which is why we employ in-house quality management and process inspection team.

Fast, reliable service– We aim to meet the demands of all of our customers quickly and effectively. Our work is not complete until you are satisfied.

Supply support capacity– We understand no two operations are the same and that different jobs require different tools- that is why we take pride in the fact that it is well-stocked with a wide, diverse range of products.

Competitive pricing– We believe we offer the best product possible for the cost.

FAQ

Guarantee

Q1: What is your product range?

A: Our range of centrifugal pumps includes slurry pumps, gravel pumps, clean water pumps, sewage pumps, and chemical pumps, both as whole pumps and spares, ceramic valves, knife gate valve, ball valve etc

Q2: What’s your MOQ?

A: Our MOQ for a centrifugal pump is 1 set.

Q3: What are your accepted forms of payment?

A: T/T, L/C, Western Union, and PayPal.

Q4: How long is your lead time?

A: In general, lead times are seven working days for a slurry pump,15 working days for a water pump, and seven working days for pump spares.

Q5: What information I need to offer a quotation?

A: Liquid:___ ; Pump Capacity___m3/h ; PH:_____ ; Pump Head: ___m ; Specific of gravity___ ; Voltage ___V ; Frequency ___Hz

Q6: Are OEM

parts available?

A: Yes. Please send a detailed drawing.

We are so confident in the quality of our pump and pump spares that we offer one of the only 100% free test and trial in the market.

We offer a free trial- if you are not satisfied after trying our Warman type pumps and spares, call us at +86 3125060076, and we will work with you to address your concerns.

If no resolution can be reached, simply return us the product, and we will refund your money, minus the shipping charges.