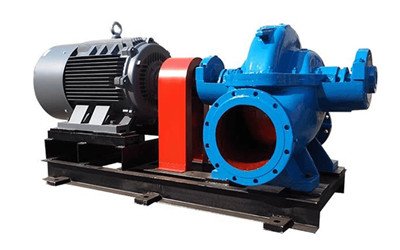

S/SH Split Case Pump

Product Description

The S and SH split case pumps are a single-stage, double-suction, horizontal centrifugal pumps used for the transportation of clean water or other liquids with similar properties, with maximum temperatures of 80˚C.

The suction and discharge ports of S and SH pumps are both located below the pump’s shaft centerline, the horizontal direction is perpendicular to the axis, and the pump casing and center are opened. There is no need to disassemble the water inlet, discharge pipe, or the motor during maintenance. When viewed from the direction of the coupling, the water pump rotates counterclockwise.

The main parts of S and SH centrifugal split case pumps are the pump body, pump cover, impeller, shaft, double-suction seal ring, shaft sleeve, and bearing, all of which are composed of cast iron, except for the shaft, which is made of high-quality carbon steel. The pump body and pump cover form the working chamber of the impeller. Pipe screw holes for installing a vacuum and pressure gauge are made on the water inlet and outlet flanges, and water pipe screw holes are made on the lower part of the water inlet and outlet flanges.

The impeller is statically balanced and fixed with the sleeve and sleeve nuts on both sides. Its axial position can be adjusted by the sleeve nut. The axial force of the impeller is balanced by the symmetrical arrangement of its blades. There may be some leftovers. The remaining axial force is borne by the bearings at the coaxial end. The pump shaft is supported by two single-row radial ball bearings. The bearings are installed in the bearing bodies at both ends of the pump body, and lubricated with “butter.” The double-suction seal ring is used to reduce water leakage from the pump pressure water chamber back to the water suction chamber.

The circulation pump is directly driven by the motor through the coupling. The shaft seal is a soft packing seal. In order to cool and lubricate the seal cavity and prevent air from leaking into the pump, there is a water seal ring between the fillers. When the pump is in operation, a small amount of high-pressure water flows into the packing cavity through the water seal tube to serve as a water seal.

Product Features

Main Application

- Large flow capacity, high efficiency.

- Easy operation and maintenance.

- Long operational life- The life of the pump casing should extend to at least 30 years, with a pressure threshold of up to 10MPa.

- The location of the inlet and outlet flange of the split case pump can be custom placed upon request.

- The shaft, impeller, shaft sleeve, and sealing ring can be composed of a selection of different materials according to the working conditions, including cast iron, cast steel, and stainless steel (SS304, SS410, etc.).

- Seal method: machinery seal and packing seal varieties available.

This model centrifugal split case pump is suitable for use in power plant, mining, city, and coal-water feeding and discharging, farmland irrigation and drainage, and all hydraulic engineering.

The Main Parameters

| Flux | 112~2600 m³/h |

| Lift | 9~140m |

| Motor Power | 18.5~850kw |

| Product Standard | GB/T5656-94 |

Split Case Pump Live Application

Pump Selection Guide

Export Slurry Pump, Chemical Pump, Split Case Pump, Sand Pump

Our Company

Over the past 15 years, Minerco has offered our clients pumping solutions to trusted the world over. Our core team of professional engineers has perfected the centrifugal slurry pump design to give you the best product on the market. Our slurry pumps and spares are interchangeable with the Warman model and parts and come with a 100% risk-free guarantee.

Our Promise- Reliable Quality & Professional Service

Your satisfaction is our number one priority. We welcome your feedback and are always looking for opportunities to improve our service. Our business philosophy is simple:

Quality control– We want to assure you of the perfection of our products, which is why we employ in-house quality management and process inspection team.

Fast, reliable service– We aim to meet the demands of all of our customers quickly and effectively. Our work is not complete until you are satisfied.

Supply support capacity– We understand no two operations are the same and that different jobs require different tools- that is why we take pride in the fact that it is well-stocked with a wide, diverse range of products.

Competitive pricing– We believe we offer the best product possible for the cost.

FAQ

Guarantee

Q1: What is your product range?

A: Our range of centrifugal pumps includes slurry pumps, gravel pumps, clean water pumps, sewage pumps, and chemical pumps, both as whole pumps and spares.

Q2: What’s your MOQ?

A: Our MOQ for a centrifugal pump is 1 set.

Q3: What are your accepted forms of payment?

A: T/T, L/C, Western Union, and PayPal.

Q4: How long is your lead time?

A: In general, lead times are seven working days for a slurry pump,15 working days for a water pump, and seven working days for pump spares.

Q5: What information I need to offer a quotation?

A: Liquid:___ ; Pump Capacity___m3/h ; PH:_____ ; Pump Head: ___m ; Specific of gravity___ ; Voltage ___V ; Frequency ___Hz

Q6: Are OEM

parts available?

A: Yes. Please send a detailed drawing.

We are so confident in the quality of our pump and pump spares that we offer one of the only 100% free test and trial in the market.

We offer a free trial- if you are not satisfied after trying our Warman type pumps and spares, call us at +86 3125060076, and we will work with you to address your concerns.

If no resolution can be reached, simply return us the product, and we will refund your money, minus the shipping charges.