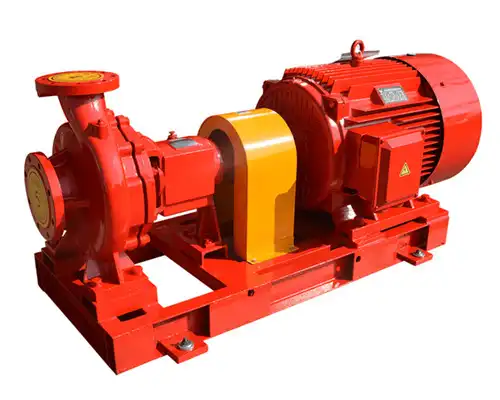

IS(R) Centrifugal Water Pump

Product Description

The IS(R) centrifugal water pump is a single-stage, single-suction centrifugal pump for the transportation of clean water or other liquids with similar physical and chemical characteristics. The medium used with the IS model should be under 80C, and under 150C for the IS(R) model.

The pump body and cover are divided from the back of the impeller, which is the so-called rear door structure, making for convenient maintenance. During maintenance, the pump body, suction pipeline, discharge pipeline, and the motor are not moved; simply remove the intermediate coupling of the extended coupling to withdraw the rotor component.

The pump casing (namely, the pump body and pump cover) constitutes the centrifugal water pump’s working chamber, impeller, shaft, rolling bearing, etc. as the pump rotor. The suspension bearing component supports the pump rotor component, and the rolling bearing receives the radial and axial force of the pump.

In order to balance the axial force of a pump, most have seal rings on the front and rear of the impeller, and a balance hole on the rear cover of the impeller. Due to the low axial force of some pumps, no seal ring or balance hole is necessary.

The axial seal ring of the water pump is composed of packing and the packing gland, which prevent air intake or a large amount of water leakage. In order to avoid shaft abrasion, a protective sleeve is installed where the shaft passes through the packing cavity, and an O sealing ring is installed between the shaft sleeve and the shaft to prevent air intake or water leakage along the mating surface.

The pump’s transmission is connected with the motor through an extended elastic coupling. The water pump rotates in a clockwise direction when viewed from the drive end.

Product Features

Main Application

- High temperature-resistant structure: The water pump body adopts the center support method, which reduces the stress involved with inconsistent thermal expansion under high temperatures and the change of the coupling to the center when the pump is transporting high-temperature media. The pump bracket, cover, suspension body (bearing part), and machine seal gland have cooling chambers, which can be cooled with water or air at different temperatures.

- Bearings: Thin-oil lubrication significantly increases the bearing capacity. Bearing life is approximately 25,000 hours.

- Shaft seal: Optional packing seal and mechanical seal available.

- Coupling: This model employs elastic column tip coupling with high precision transmission.

- Auxiliary pipeline: This pipeline is configured according to the standards of the 8th edition of the API 610.

- High-pressure design: 4.0MPa

The applications include water supply and drainage in locations and industries including electric power stations, metallurgy, weaving, chemical, dyeing, ceramics, rubber, heating, heating and air condition utilities, and agriculture irrigation and drainage.

The Main Parameters

| Flux | 6.3~400 m³/h |

| Lift | 5~125m |

| Motor Power | 0.55~110kw |

| Product Standard | GB/T5656-94 |

Centrifugal Water Pump Live Application

Pump Selection Guide

Export Slurry Pump, Chemical Pump, Water Pump, Sand Pump

Our Company

Over the past 15 years, Minerco has offered our clients pumping solutions to trusted the world over. Our core team of professional engineers has perfected the centrifugal slurry pump design to give you the best product on the market. Our slurry pumps and spares are interchangeable with the Warman model and parts and come with a 100% risk-free guarantee.

Our Promise- High Quality & Professional Service

Your satisfaction is our number one priority. We welcome your feedback and are always looking for opportunities to improve our service. Our business philosophy is simple:

Quality control– We want to assure you of the perfection of our products, which is why we employ in-house quality management and process inspection team.

Fast, reliable service– We aim to meet the demands of all of our customers quickly and effectively. Our work is not complete until you are satisfied.

Supply support capacity– We understand no two operations are the same and that different jobs require different tools- that is why we take pride in the fact that it is well-stocked with a wide, diverse range of products.

Competitive pricing– We believe we offer the best product possible for the cost.

FAQ

Guarantee

Q1: What is your product range?

A: Our range of centrifugal pumps includes slurry pumps, gravel pumps, clean water pumps, sewage pumps, and chemical pumps, both as whole pumps and spares.

Q2: What’s your MOQ?

A: Our MOQ for a centrifugal pump is 1 set.

Q3: What are your accepted forms of payment?

A: T/T, L/C, Western Union, and PayPal.

Q4: How long is your lead time?

A: In general, lead times are seven working days for a slurry pump,15 working days for a water pump, and seven working days for pump spares.

Q5: What information I need to offer a quotation?

A: Liquid:___ ; Pump Capacity___m3/h ; PH:_____ ; Pump Head: ___m ; Specific of gravity___ ; Voltage ___V ; Frequency ___Hz

Q6: Are OEM

parts available?

A: Yes. Please send a detailed drawing.

We are so confident in the quality of our pump and pump spares that we offer one of the only 100% free test and trial in the market.

We offer a free trial- if you are not satisfied after trying our Warman type pumps and spares, call us at +86 3125060076, and we will work with you to address your concerns.

If no resolution can be reached, simply return us the product, and we will refund your money, minus the shipping charges.